Straight vs. Tapered Countersink Bits: Which One Should You Choose?

When working on woodworking, metalworking, or DIY projects, using a countersink bit is essential for creating clean, flush screw installations. However, when it comes to choosing between a straight or tapered countersink bit, the decision isn't always straightforward. Each type of bit has specific advantages depending on the material, the type of screws you're using, and the nature of the project. To make the right choice, it's important to understand the differences between straight and tapered countersink bits and when each is most effective.

A straight countersink bit has a cylindrical body with a conical tip designed to create a perfectly round, straight hole. These bits are ideal for general-purpose countersinking, particularly when working with screws that have flat or oval heads. Because of their uniform diameter, straight countersink bits create holes that match the width of the screw head, allowing the screw to sit flush with the material. This makes them a popular choice for projects where a clean, finished look is important, such as cabinetry, furniture making, or installing hardware like hinges.

One of the primary advantages of using a straight countersink bit is its versatility across a variety of materials. Whether you're working with wood, metal, or plastic, a straight bit provides consistent, even results. Straight countersink bits are also often used in situations where precision is key, such as in fine woodworking or metal fabrication, because they produce a smooth, clean edge that minimizes the risk of damaging the material. For general-purpose tasks where screws are meant to sit flush with the surface, straight bits are usually the go-to option.

On the other hand, tapered countersink bits are specifically designed to accommodate tapered screws. Unlike straight screws, tapered screws narrow toward the tip, and the tapered countersink bit creates a hole that matches this shape. This design is particularly useful in woodworking projects where tapered screws are commonly used to increase the holding power in the material. The taper of the screw allows for better grip, particularly in softer woods, and reduces the likelihood of splitting the material. The countersink bit, in this case, ensures the screw head sits flush while still providing that added grip advantage.

Tapered countersink bits are favored by woodworkers who need a strong, durable joint, such as in cabinetry, furniture construction, or outdoor woodworking projects. The tapered design distributes the screw's load more evenly across the wood fibers, creating a more secure hold, especially when working with softwoods like pine or cedar. Because tapered screws are often used in structural applications, the tapered bit ensures that the hole provides optimal support for the fastener, reducing the risk of the screw loosening over time.However, tapered countersink bits may not be suitable for every project. If you're working with flat-head or straight screws, using a tapered bit can lead to inconsistent results. The hole may not match the screw properly, resulting in a loose fit or uneven countersink, which can compromise both the appearance and functionality of the project. In this case, it's important to ensure that the screw type and bit design are compatible to achieve the desired outcome.

Another factor to consider when choosing between straight and tapered countersink bits is the depth of the countersink. Some projects require the screw head to sit deeper in the material, such as when the screw will be covered with a wood plug or filler. Tapered countersink bits are often better suited for deeper countersinking, as their design allows for more gradual material removal. Straight bits, on the other hand, create more shallow, uniform countersinks, which are ideal for projects that prioritize surface-level aesthetics.

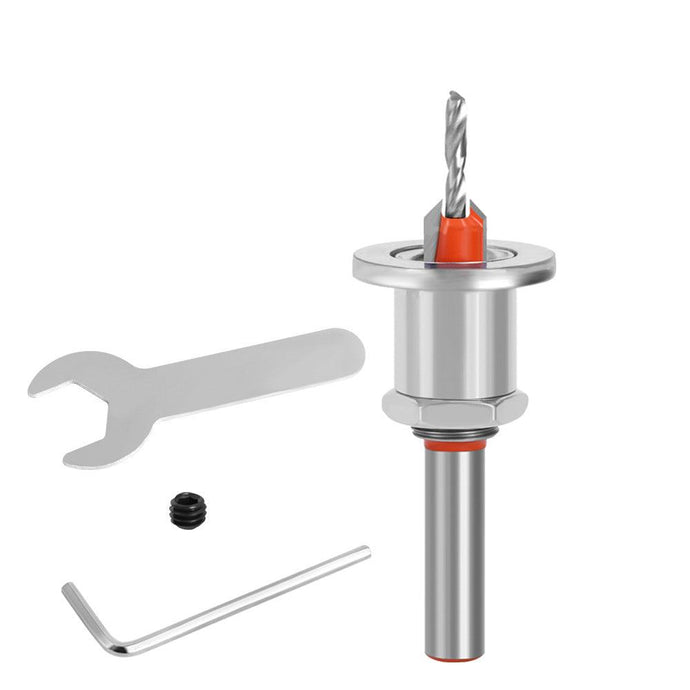

It's also worth noting that some countersink bits are adjustable, allowing you to modify the depth of the countersink to match the needs of your project. This feature is available in both straight and tapered bits and can be especially useful for ensuring consistent countersink depth when working with multiple screws. Adjustable countersink bits are commonly found in combination with drill bits, which means they can drill the pilot hole and countersink in one step, improving efficiency and accuracy.

Ultimately, the choice between a straight or tapered countersink bit comes down to the type of screw you're using and the requirements of your project. If you're working with flat-head screws and need a clean, precise finish, a straight countersink bit is likely the best option. It offers versatility across various materials and provides consistent results, making it suitable for most general-purpose projects. On the other hand, if you're using tapered screws in a woodworking project that requires extra holding power and durability, a tapered countersink bit is the ideal choice. It complements the tapered screw's design and ensures a stronger, more secure joint.

By understanding the differences between these two types of bits and considering the specifics of your project, you can make an informed decision that leads to better results. Whether you need precision, strength, or both, choosing the right countersink bit will help you achieve a professional finish while ensuring the screws in your project are secure and properly aligned.